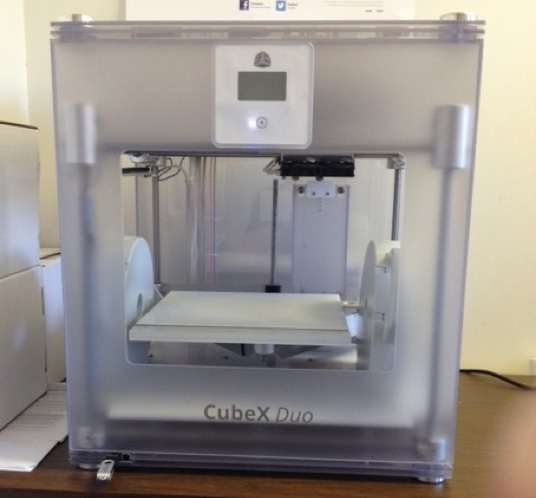

Windsor’s design engineering group recently purchased and implemented a new 3D printer for the department. 3D printing allows us to make true-to-size, three-dimensional models of various parts, components and lineal profiles out of ABS plastic material. The 3D printer interfaces with AutoCAD Inventor 3D files. Printing can take from 1 to 20 hours per part, depending on the size and complexity.

Our CubeX printer will print objects as small as a screw all the way up to the size of a basketball. Having 3D printing capabilities allows the design group to more quickly and efficiently test and trial not only individual parts and pieces, but also mating or joining parts, such as sash and frame members, weather-strips and entire framing systems.

The new 3D printer is a significant enhancement for the design engineering team, shortening the product development and R&D process.

CubeX 3D Printer

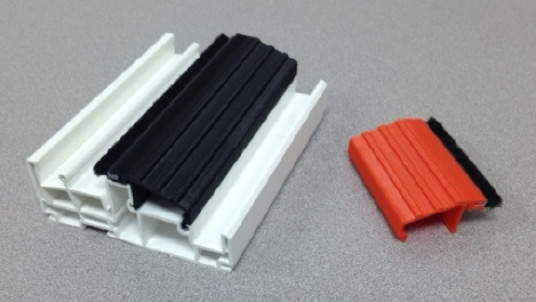

Patio Door Sill and Threshold Printed Samples

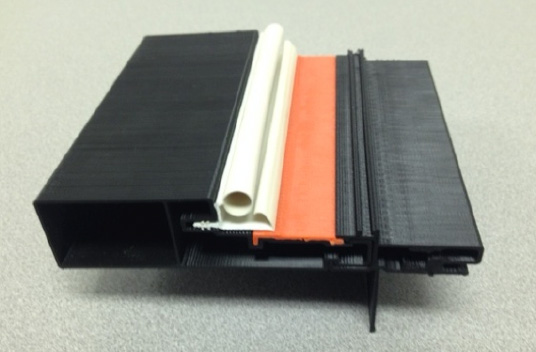

Clad Swing Door Frame with Thermal Break Printed Sample